Electronic circuit repair stands out as a critical service for the sustainability of modern industrial equipment. This process involves the accurate detection of faulty components, the replacement of necessary parts, and the reprogramming of the circuit board. The circuit boards used in industrial machines are often expensive and have customized components, making electronic circuit repair an economical and environmentally friendly solution compared to purchasing a new circuit board.

For more detailed information, you can check out our blog post titled "What Is Electronic Circuit Board Repair?"

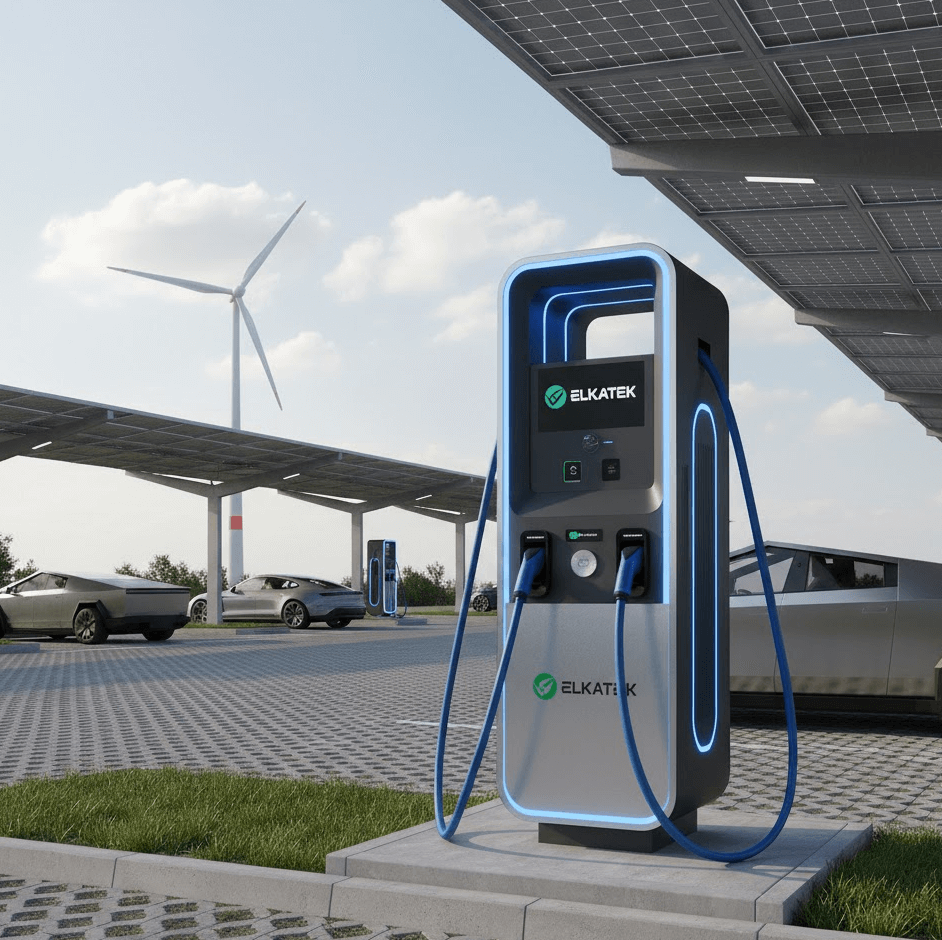

Elkatek Elektronik, Your Reliable Solution Partner!

We offer a wide range of services, from electronic card repair to test device sales, from electronic component supply to PCB board production.

In this journey that we started with Ankara as our center, we are proud to provide fast and reliable service to all corners of Turkey. By keeping customer satisfaction at the forefront at every step, we are constantly improving ourselves to provide you with the best service.